As we were returning from rug shopping, Jeanine and I were treated to a spectacular sunset over the Sudbury River. Our timing could not have been more perfect and I am thankful for this gift of light.

Yesterday, we obtained a temporary certificate of occupancy for the River House!!! All that remains to be done before obtaining our final CoO is to submit an updated as-built plot plan that includes the roof overhangs. Our surveyor will be here on Sunday to take the necessary measurements and we should have the needed drawing by Monday.

In the meantime, we are free to start moving in which we have decided to do gradually, one carload at a time. My nephew, Rory, helped out with Jeanine’s stationary bike which will initially be located in her sanctuary. The gradual move allows us to organize the new house one room at a time. In about a week, we will be ready to rent a small van to move the larger items over.

The second episode of The Build Show covering our home just dropped. Host Matt Risinger and our architect Steve Baczek cover several aspects of the interior space including my shop, the mechanical rooms, the kitchen, the front door, the master bathroom, and the stairs.

Now that all the requirements for occupancy have been addressed, I am moving on to the design and construction of the built-ins for our walk-in closets. Jeanine completed an inventory of all her clothes, shoes, and accessories so that I can ensure they will each have a proper-sized space. I have not done the same exercise but should be fine if I allocate myself half of what she needs. Pictured above is an initial concept which is sure to undergo refinement. It features 16 drawers, spaces for 54 pairs of shoes, 11 feet of lineal hanging rod, 20 large shelves, and a countertop.

At long last, we had our final inspections for the River House today. We passed our energy storage system (battery backup) electrical, fire, and building inspections. Only the permitting for the Natural Resource Commission has been more arduous than the battery. Because the technology is so new, the fire inspectors have approached the whole situation with an overabundance of caution. The next Concord family that decides to install an ESS will have us to thank for blazing the trail.

We were not so fortunate with our occupancy inspection. We failed on two counts. (1) We have been using the area under the landing for our basement stairs as a storage area for leftover paint and tile. Access to the space was by way of a 45″x 30″ opening. By code, the interior of this space needs to be finished with 5/8″ gypsum wallboard to impede fire propagation. The amount of work to do this in such a confined and irregular space would not be worth the benefit. Our other option was to permanently seal off the access opening which is what I opted to do. Pictured above is the final result which I completed after a run to Home Depot for the materials. (2) The door to the garage needs to be self closing. The one we have is equipped with self closing hinges but they had not been engaged. I attempted to do so, but a manufacturing defect in one of the hinges prevented me from finishing. I have called our builder to address this problem as it should have been installed with the springs engaged in the first place.

It would have been nice to pass on our first attempt, but I am thrilled that our punch list is so short. As soon as the garage door is addressed we should be good to go.

My nephew Rory has been visiting for the past week and will be with us for the next. He is an talented personal trainer among other things. Nico invited him to Boston for an intense week of physical training and healthy eating. His amputee soccer teammate, Jovan is also staying at the Road House and participating in the training/eating regime. Regrettably, I have been so occupied with preparations for the final inspection at the River House that I have spent very little time with him thus far, a situation I plan to rectify in the coming week.

Maya is dog-sitting for Bella again and joined us at the River House this afternoon before embarking on the continuing repairs of her tiny house. Bella is the best-trained dog I have ever known. She can do a handstand or jump up onto Maya’s back on command. She is also adorable and very cuddly once she gets to know you.

For the last 8 months or so, I have been operating without a shop sink, something that is quite essential when working with glues and finishes. During the first 4 months, I had to go upstairs and outside to the detached garage where our temporary water service was located. Talk about inconvenience. Once the water service was connected to the house, I only needed to walk upstairs to the laundry room, a monumental improvement but still not ideal. Today, I decided it was time to install the sink I had planned for my shop. Because our septic tank is located above the level of the basement a lift pump is needed to pump the drain water up to the main drain line. I had the plumbers leave stubbed lines for the drain, vent, and water supply lines near the shop ceiling in anticipation of this day. The first order of business was to build a cabinet carcass and mount it to the wall. While I was at it, I decided to repurpose a set of floor standing shelves into a wall mounted version. Next, I connected the lift pump (lower left) to the drain, vent, and discharge pipes and plumbed in the hot and cold water supply lines and shutoff valves. Finally, I added the countertop, backsplash, sink and faucet before connecting up all the hoses and wiring . The faucet can be turned on and off with a gesture – very convenient when your hands are covered in varnish and hence the need for wiring. Eventually, I will add drawers and doors to the front of the cabinet but for now I am very content to have an operational sink no more than a few steps away.

Jeanine and I are spending nights at the River House to free up beds for our guests at the Road House. Visiting from Seattle is our nephew Rory who is here to help Nico and his amputee soccer teammate Jovan, our other guest, with 2 weeks of intense physical training. We woke up to about an inch of fresh snow and Jeanine can be seen here enjoying her morning coffee.

At long last, the stairs and railings are done. I put the final coat of finish on this afternoon and we are now ready for inspection. In total, the railings took about 3 weeks of build time, and the stairs about the same. If I had known just how much work would be required, I might have opted for a turnkey solution. On the other hand, the savings we realized could purchase a small new car. I am most appreciative of my gluing and finishing assistants, Jeanine and Nico.

After weeks of work all 150 balusters, 7 Newell posts, 4 hand rails, and 3 guard rails have been permanently installed. The final step was to glue top caps to the Newell posts. We are now officially ready for inspection by the building department and hope to have our occupancy permit shortly. Tomorrow, I will do some final sanding and finishing work and then move on to built-ins for our walk-in closets.

To maximally stabilize the Newell posts I am constructing for the River House, I decided to channel them through the end of the stair tread before fastening them to the floor. This adds a considerable amount of strength at the expense of a rather complicated mating joint with multiple critical dimensional tolerances. Machining these was possibly the most stressful work I have done on the house thus far The slightest mistake on either part would have resulted in a depressingly large amount of rework. I perfected my approach on scrap material before attempting the work on the final components and thankfully this led to a successful outcome.

I installed three out of seven Newell posts today. More accurately, I installed three-quarters of each post. I have left one side open so that I can secure the railings with a bolt driven from the inside. Tomorrow, I will glue on the missing face and top cap. The base is glued to a cleat that is the same size as the inside of the hollow post. The cleat is secured to the floor with a massive lag screw. If tomorrow goes smoothly, I should be finished with the railings by the end of Monday and we will then be ready for our certificte of occupancy inspection. Fingers crossed.

Thanks to our neighborhood list server, I was alerted to the approach of a bevy of swans, 13 in total. I was able to grab my good camera and photograph them as they swam past the house. Ice has begun to form near the banks but the bulk of the river is still flowing. If I had to guess, I would say they were having a leisurely swim, resting from what was likely several hundred miles of flying. Jeanine arrived at the house shortly after they passed by on the water but spotted them in the air as they resumed their migration.

I completed the last three railings for the staircase today by machining the holes needed to connect and secure the balusters to the rail. The anatomy of the rail is pictured below. The balusters are slid over the connector to mate with the rail at an angle of 32.5 degrees. The ends of the rails have a threaded metal insert that will accept a fastener to secure it to the Newell posts. One end of the rail has a 16.25 degree compound joint followed by a mitered right angle return. The rail itself was made by laminating non-overlapping 4 foot long sections of bamboo plywood together (for a perfect match to the stair treads).

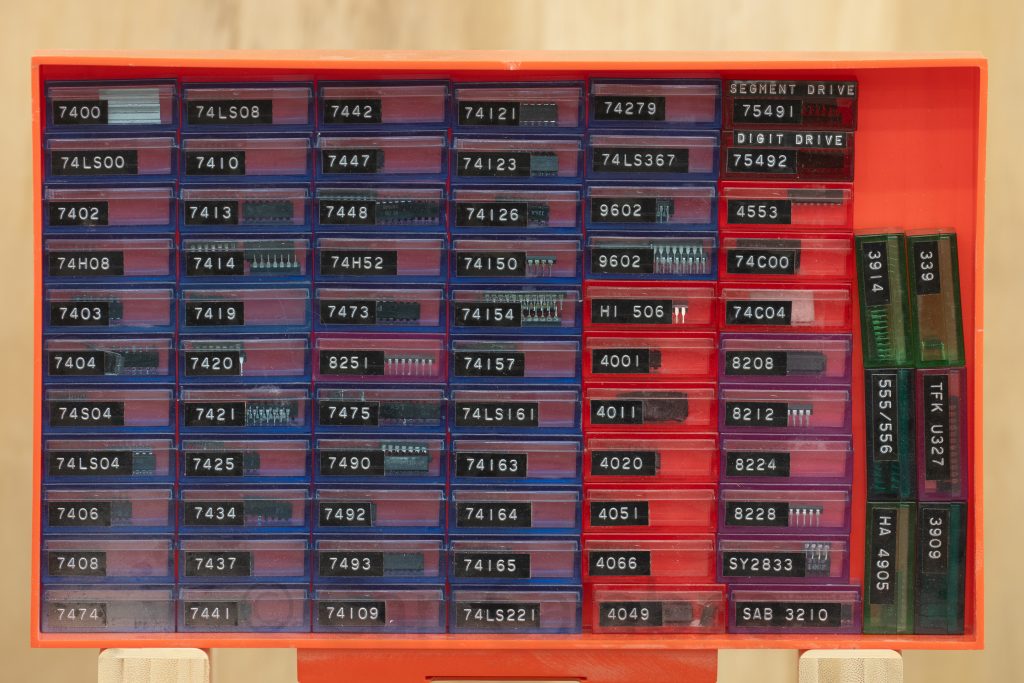

Although my college degrees are in Electrical Engineering, it is only because the field of Computer Engineering was in its infancy. My primary concentration was in logic design and computer architecture. Even the most advanced computers today are still based on the same basic building blocks that perform the logical operations of AND, OR, and NOT. When I was in grade school, these logic elements were constructed out of individual transistors. By the time I was in high school, they had become available on integrated circuits that offered multiple gates, shift registers, flip-flops, multiplexors, and a bunch of other more sophisticated functions. Pictured above is the collection of chips I assembled while in college so that I could quickly prototype my ideas. My first self directed design was a 16-channel logic analyzer which won me the Stearn’s Prize awarded to the outstanding student in electrical or computer engineering at Union College.

Alas, It has been more than three decades since I built anything from these parts and I decided that they would not be making the move to the River House. Jeanine and I are making a concerted effort to get rid of all of the things we have accumulated over the years but no longer use.

Today, I decided to make a timelapse video of a typical day in the shop. Unfortunately, or fortunately depending on your perspective, my camera ran out of both storage space and battery so only two hours were captured. The video lasts less than 2 minutes and shows the construction of seven Newell posts. Order of operations: Rip boards to 3-inch width, cut to length at the miter saw, move to the router table to create a lock miter joint along all edges (most time-consuming), return to the table saw to make relief cut in half the boards to prevent tearout, empty the dust collector at some point, dry fit the Newell posts and move on to routing and sanding the hand rail I glued up earlier in the day. Not shown, the other 6 hours of work before returning home to snow blow the driveway. Gotta love retirement?

Shoptimization continued today. First, I moved my tablesaw and jointer/planer 6 inches to the east. This small change permits me to machine 10-foot long stock which was not possible before. Second, I built a set of shelves for my cordless tools that are now located under the picture window. Moving them from their previous location also opens up the space where I plan to install a sink one day. Third, I consolidate all my tools on the north wall of the shop where they are close at hand to my assembly tables. Fourth, I located my drill press on the east wall and repurposed a portable shelving unit I made for my old shop for drill bits and accesories. When all was said and done, I moved every last thing in my shop except the bandsaw and miter saw. I am very happy with the final layout and do not plan to make any future changes.

The remaining bamboo plywood needed to complete the stair railing for the River House is scheduled to arrive tomorrow and I found myself with a free day. I decided to spend the time optimizing my shop, a process I call “shoptimization.” With six months under my belt, I had a very clear plan for the changes I wanted to make. First, I moved my router table to where the drill press used to be. I aligned the table height with that of the miter saw to take advantage of a free outfeed table. Second, I moved my “harware store” (small part cabinets with all manner of screws, nuts and bolts, etc.) from the north wall to the south wall. This freed up some prime real estate where I will locate more frequently accessed tools. Third, I moved my sanding station from next to the outside door to the corner where the router table used to be. This location allows me better access to the machine and is already plumbed for dust collection. Tomorrow, I will figure out where to locate the displaced drill press.

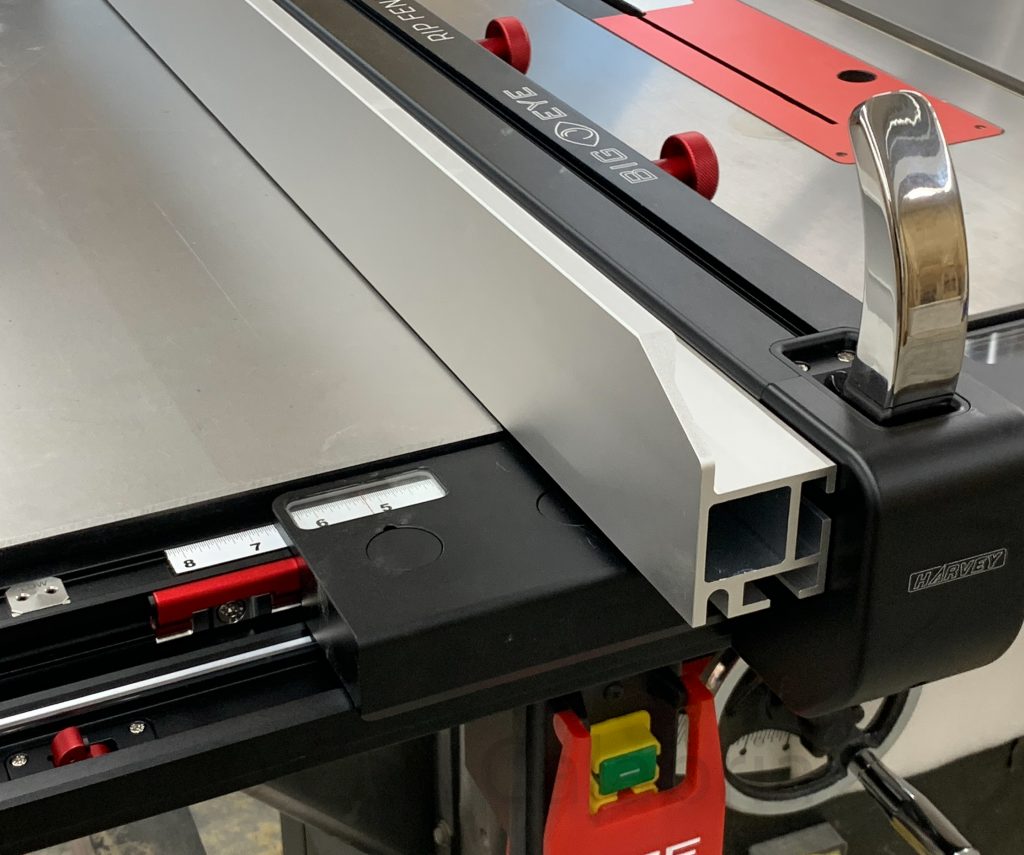

Pictured above are the angled ends of two 8-foot-long handrails. the first joint takes the diagonal rail back to horizontal and the second turns 90 degrees to mate with the Newell post. Each rail has 20 recessed holes on the underside angled at 32.5 degrees where the baluster will be situated. Each recess has a smaller and deeper hole drilled in the center where a 3D-printed baluster connector will be fastened with a screw. In total, each rail requires more than 60 machining operations and a dozen glue ups. A single mistake can render the entire rail unusable which makes for very stressful work. Fortunatley, these two rails came out perfectly and today they were treated to two coats of sealer and two of a protective finish. During the 2 hours of drying time between each coat, I installed a new fence on my table saw. I ordered the device back in September and have been patiently anticipating its arrival. All I can say, is that it was worth the wait and every penny I paid for it. I then cut down and fitted the original fence to my bandsaw and scrapping the piece of crap it was supplied with.

Jeanine presented me with an odd request today. She wanted me to drill a couple of holes through the edges of a pair of sea shells so she could sew them onto a garment. I am sure there is a way to do this without destroying the shells in the process but I decided it would be far easier to glue a couple of loops to the back through which the thread could be passed. Jeanine was in charge of fabricating a superhero-themed outfit for “Island Woman”, one of her friends who is celebrating her 60th birthday.

Even though it was explained to me, I remain unclear about why Jeanine is dressed as Fanny Wheeler, an important figure in Concord’s history. Something about a secret society.

I was dressed as a stair railing contractor and completed 5 of the 7 railings needed to apply for our occupancy permit. I am using 3D-printed parts to connect the railing to the balusters. These can be seen in the photo below where the railing is turned upside down with the printed parts screwed into the bottom of the railing.

Only another soccer player can fully appreciate the amazing goal that Nico scored during a match against rival New York recently. The degree of difficulty of this shot is off the charts! (a) It is a one-touch strike on a moving ball, (b) it is taken from a great distance, (c) it is placed just inside the post. Nico has scored some truly amazing goals throughout his career but for me, this may be his best. Using the known length of his crutch as a measurement reference, I estimate this shot was taken at a distance from goal of 64 feet. Keep in mind that amputee soccer goals are smaller than standard ones measuring only 7’x16′. Compare Nico’s strike to Stephen Gerrard’s famous equivalent. I think any professional footballer would be envious of Nico’s banger.

I couldn’t resist a second post featuring our first snow of the season. Today, blue skies and sunshine replaced the gray and cloudy skies of yesterday. The forecast is calling for rain tomorrow so this winter wonderland landscape will soon be gone. This photo of the Sudbury River is about a quarter of a mile downstream from our new home and the bridge is one we cross daily to go almost anywhere.

Thus far, this winter has been quite mild. Today, we got our first proper snowfall, a total of about 9 inches which started during the night and fell throughout most of the day. I took these drone photos about one-third of the way through the storm during a lull. Jeanine and I spent the entire day at the River House working on the stair railings. We made reasonable progress despite a few minor setbacks.

With Jeanine assisting me all day, we made excellent progress on setting balusters in place on the stairs from the first to the second floor. Weather permitting, we hope to do the same for the stairs to the basement tomorrow. A snowstorm is currently forecasted to dump half a foot of snow on us throughout the day. The work goes slowly because of the need for accuracy and the high cost of even a small mistake. While the balusters are being installed permanently, all the newell posts and rails are temporary and will need to be replaced when the bamboo needed for their construction finally arrives.

The first of two episodes on the Build Show featuring our River House project dropped today. In it, our architect, Steve Baczek discusses aspects of the design with host Matt Risinger.

Last week, FedEx attempted to deliver two pallets of plywood that I ordered weeks ago. The first pallet was as ordered. The second contained long boxes and not the 4’x8′ sheet goods I was expecting. I accepted the first pallet and rejected the second. Naturally, the missing plywood is what I need to complete the stair railings. The supplier acknowledged the error and is shipping out the correct material but it will probably take several weeks for that to arrive. Since our occupancy permit is gated by the completion of the stair railing, I have opted to proceed using scrap plywood that I will later replace with bamboo. This morning, I built and installed 7 temporary newell posts (three visible in the photo, the remainder are on the floors above and below). I then installed all the balusters for the guard rails on a spacer rail that will hold them in the correct position until I can epoxy them to the lag screw studs in the floor. Once cured, I will replace the spacer rail with a temporary code compliant railing. Next, I will repeat the process for the stair hand rails. On a positive note, I really like the shadow pattern generated by the balusters.

Nico was recently featured in an AdaptX podcast interview. The extensive conversation is centered on the work he is doing with the Bionic Project as well as his crusade to build a world-class amputee soccer program in the US. I am extremely proud of the work he is doing and how eloquently he speaks about it. If you can set aside an hour to listen to the full interview, I promise you will learn some things that will change your perspective regarding people with a disability.

With the holidays in the rearview mirror, it was time to get back to work on the River House. I used an abrasive cutoff disc in my grinder to remove the heads of ~150 half-inch lag screws. It was not a pleasant task. I had to wear a respirator, protective goggles, and hearing protection for my safety and used the galvanized steel jig below to protect the stairs and floors from the spark generated by the grinding process. It took me about a minute to decapitate each screw which translates to about 2 1/2 hours bent over with a heavy grinder. Jeanine was kind enough to give me a back rub that helped alleviate the pain. I also began to erect the temporary scaffolding that will hold the balusters in place while they are glued to the studs on the floor.