Perhaps the most complex element of my new shop is the dust collection system. This includes the dust collector with removable waste bin, the in-ceiling ducting which connects it from the mechanical room to my shop, the individual machine drops which include a pneumatically controlled blast gate (my design for this illustrated above), and the electrical components to automatically sense when to turn on the dust collector and which blast gate to open. Today I installed the contactor that will be used to energize the dust collector anytime a wood chip-producing machine is turned on. A current sensor in the electrical panel will determine when any machine on the dedicated circuit is operating and will activate the contactor. A current sensor on each machine’s power supply will cause the associated blast gate to open. I hope to have my shop operational within the next 2 months and look forward to starting cabinet construction for the kitchen.

Easter Friends

We missed Maya at our Easter gathering this afternoon but were happy to be joined by Fallon, Nico’s girlfriend, Marisa, Kyle’s roommate, and her dog Bailey. Jeanine prepared a fabulous lamb shawarma with saffron rice and a broccoli salad. Maya is flying back from the UK where she has been on vacation for the last 9 days. My soccer team suffered a major drubbing this morning losing 0-3 to the top team in our league. All that can be said about my play was that I did not get injured.

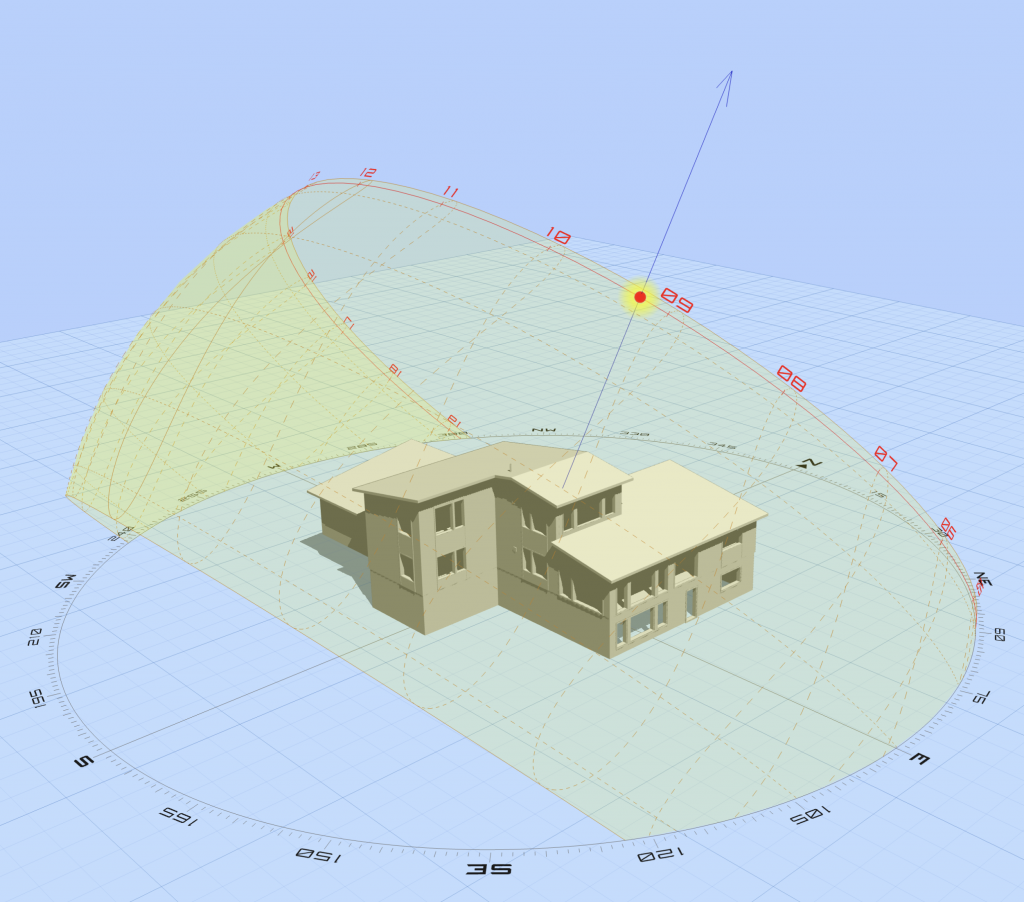

Sun Angles

Given all the trees which surround our River House, I have been struggling with whether or not to put solar panels on the roof. An invaluable tool to help with the analysis is a sun path calculator which I finally figured out how to load with a model of our house. My conclusion is that we will break even on the cost of panels over a period of twenty years but that it is still probably the right thing to do.

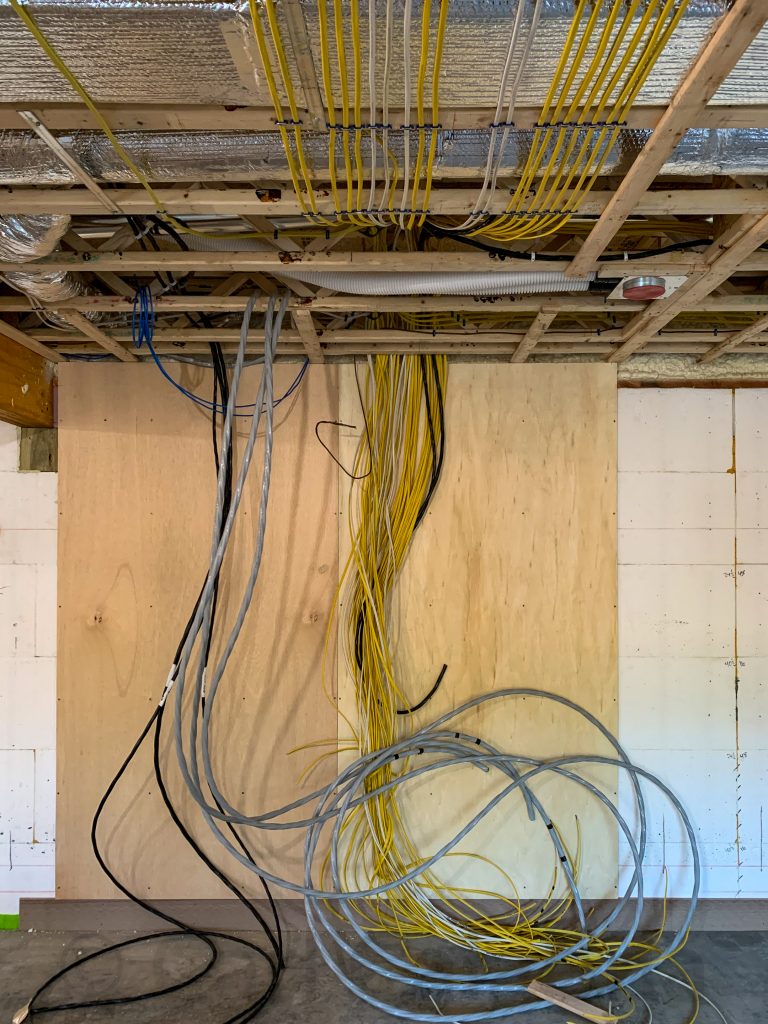

Wiring Jungle

Rough wiring for the River House is approaching completion. Pictured above is where the automatic transfer switch and main breaker panel will reside within my shop. In total the house will have one main and 4 sub-panels; one in the primary mechanical room, one in the secondary mechanical room, one in the laundry, and one in the garage. The cost for multiple panels is far outweighed by the savings for shorter copper runs within the house. The automatic transfer switch will allow our battery backup system to kick in during a loss of power to the house and to time shift our use of electricity. During off-peak hours the batteries will charge and during peak hours will be used to power the house. Concord is switching to time-of-use metering so this capability should allow us to significantly reduce our electrical energy costs.

Teppanyaki Excitement

My sister and brother-in-law just moved into a new home that features a teppanyaki grill in the kitchen. Apparently, Stephen was very excited about his first cooking experience in the new kitchen or was attempting to channel the energy of a traditional Japanese chef. Either way, here is what I am expecting to see when we go for our first visit.

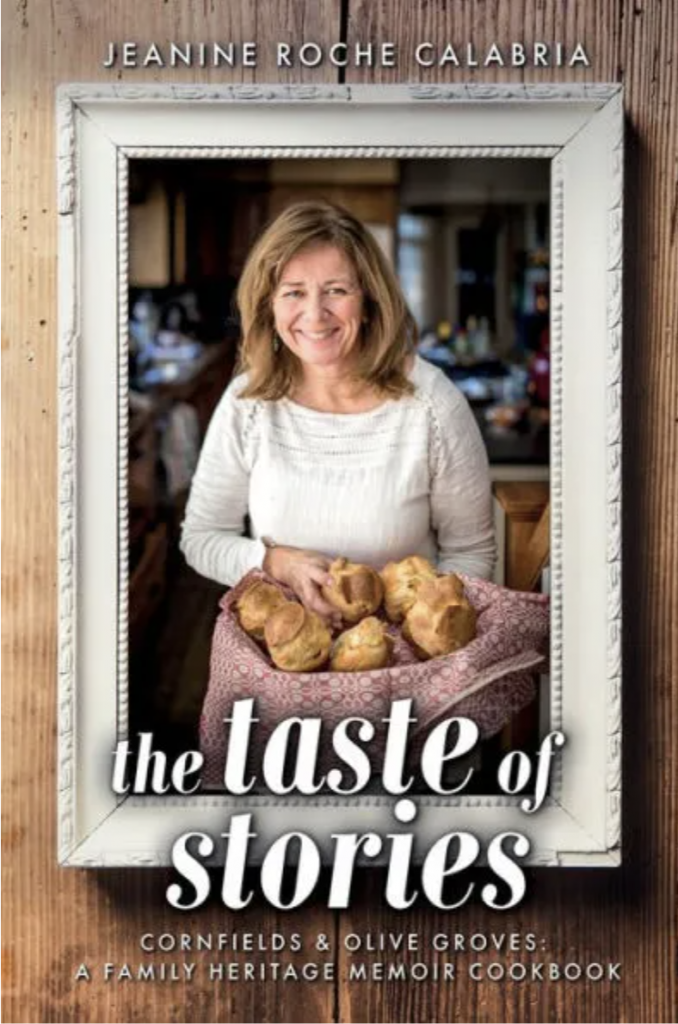

The Taste of Stories

Fifteen years in the making, Jeanine’s memoir cookbook is now going to print. Available for pre-order from Barnes & Noble and Amazon, it is expected to ship next week on her 60th birthday. I am very proud to be married to such a wonderful writer and creative cook. Having only heard small snippets of the text over the years I am looking forward to reading it from cover to cover. Now that she is on the verge of fame, salacious gossip has already surfaced about her private life. Apparently, she had a torrid affair with the book’s photographer the entire time she was writing it.

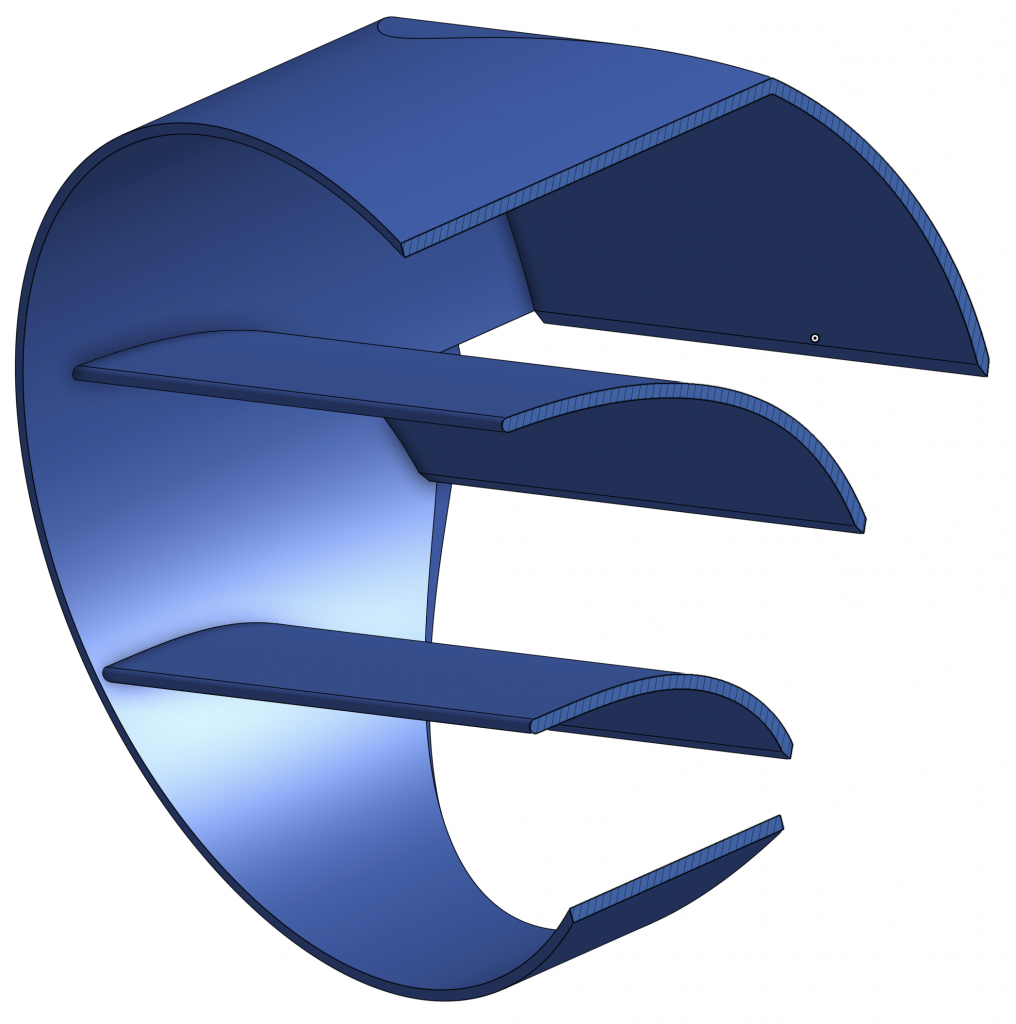

Dust Collection

Pictured here is the dust collector that will service my new shop. I have located it in the mechanical room across the hall so that I will not be assaulted by the din generated by such machines while I am working. It appears to be standalone but is actually suspended on the wall. The bin at the bottom is actually an inch off the floor and is lowered onto its casters when it is time to be emptied. Unlike my previous dust collector, this unit is based on a high-pressure three-fan air mover and is about half the size with ducting that is half the diameter. I spent a good portion of the day assembling and installing it. I had to remove the magnetic motor starter and rewire it to start when I turn on any piece of equipment in the shop connected to the system. Keen observers will note the absence of floor molding and a rather unusual construction detail at the base of the walls. Living so close to the river, it only seemed wise to anticipate that one day we could potentially have a flooded basement. With this in mind, the base of the walls and molding are constructed of a product made from rice hulls which is totally impervious to water and could sit in it for months with no ill effect. The molding has yet to be installed in the mechanical room and hence the 6 inch gap between the plywood walls and concrete floor. Today, little was left of the fire that we built yesterday to get rid of the fallen tree limbs from over the winter.

Big Hike

NY vs NE

Two Calabria’s returned to the soccer pitch this morning. Nico played in a regional game pitting the NY Metro team against his New England Revolution team. Reporting on the match from Jeanine was light on game details but I am informed that Nico’s team won and that he scored at least one goal. I was unable to attend because the match time conflicted with my spring season opener against Nashoba. We dominated the game winning 5-0. One of the goals was mine scored off a really pretty header from just outside the 6-yard box. The cross from the touchline did not have much on it so I had to really generate a lot of power with my neck to snap it past the keeper.

The videos above were recently published and cover some of the recent activities of the American Amputee Soccer Association.

Booty Vortex

Rough Grading

In preparation for siding work which is scheduled to commence next week, the site work subcontractor came in today to do a quick rough grade. This will make it easier to position ladders and scaffolding for that work. I could really use one of the baby Kubota’s.

Failure Analysis

I spent part of the day working on a failure analysis of a high-pressure pump head used in one of the instruments I helped to design for a client. I am fairly confident that I have determined the root cause of the failure and these photos will be part of my report. A substance, which I have yet to identify, is accumulating on the glass piston rod and mating high-pressure seal which increases the friction between these components enough to prevent normal piston motion.

Boston Children’s Museum

Repeating my early morning drive into Boston from yesterday, I had time to stroll over to the Boston Children’s Museum before another all-day meeting with a client.

Located in front of the museum is the Hood Milk Bottle concession stand. The 40-foot, 15,000-pound structure was created in 1933 by Arthur Gagner as a roadside ice cream stand in Taunton, Massachusetts, becoming one of America’s first fast food drive-in restaurants. It stood as a landmark on Route 44 until it was abandoned in 1967. Hood bought the Milk Bottle, renovated it, and donated it to the Boston Children’s Museum in 1977. Sadly it does not open for business until 11 am and closes at 5 pm during which time I will be working.

Breathe Life Together

“Breathe Life Together” is the title of Rob “ProBlak” Gibbs mural on the Rose Fitzgerald Kennedy Greenway Conservancy in Dewey Square. The mural is a giant, mostly black-and-white depiction of the artist’s 3-year-old daughter, Bobbi Lauren, wearing a tracksuit in front of a 1980s-era boombox. It was completed in June of 2022 and greeted me on an early morning stroll down Atlantic Ave. I drove into Boston early to beat the traffic for an all-day meeting with one of my clients and really enjoyed walking the area. I have another such meeting tomorrow and hope to further explore this part of downtown.

Cheese Popover

Perfect Pancakes

The kids joined us for a pancake brunch this afternoon. Jeanine whipped up the buttermilk batter and I was in charge of cooking and flipping, jobs I take rather seriously. Controlling the griddle temperature on a gas stove was a losing proposition and I am looking forward to the induction cooktop we will have in our new house. Despite the challenges of keeping the pan at 375F, I managed to produce some rather fine-looking pancakes. Maya heads to the UK next week with a large group of her high school friends and it was fun to hear about all that she has planned. Nicolai had just come from his girlfriend’s birthday party where he met her parents for the first time.

Shower Install

Kyle and I installed the shower in his new basement bathroom. We were both very pleased with the results. The unit is a perfect fit for the space and the sliding door works like a charm. All that remains to be done is the installation of the shower head. The job took longer than we expected because we had to stop in the middle to locate and buy a diamond-tipped drill bit to make 8 holes through the porcelain tile which was entirely impenetrable with the carbide-tipped bit we started with. While we worked on the bathroom, Jeanine did a thorough job of de-stapling and cleaning the stairs after we removed the worn-out carpeting.

The Octopus

I managed to complete the installation of our Zehnder ERV in the River House today. In total, the system has six 8″ trunks; two for the outside intake and exhaust (which must be insulated and appear at the back of the unit, two for the west wing supply and extract (going through the wall), and two for the east wing supply and extract (up into the joist bays). Insulating the outside intake and exhaust ducts took 4 times as long as all the remaining work and was my least favorite part of the job. The whole thing looks a little like an octopus but I am pleased that I kept the ductwork confined to the footprint of the ERV so as not to encroach on the rest of the mechanical room.

Perfect Fit

Lunch Break

Today’s crew included our site supervisor, Arel Electric, and M&R Plumbing. Pictured here on their lunch break, the team has been doing outstanding work. The old carport and garage continue to serve as a makeshift office and storage area, respectively. Both will be demolished when we reach the end of the project.

Water View

Mark Your Calendars

Construction Dudes

Jeanine took this photo of Kyle and me after we completed the installation of his new refrigerator, dishwasher, induction range, and microwave oven. It took us all day to complete the electrical and plumbing. We took a break at noon to enjoy a family brunch courtesy of Jeanine. We were joined by Maya as well. Nicolai is in New Jersey at an amputee soccer training session and was missing from the family meal. Next up, Kyle and I will focus on completing the bathroom and interior door installation. The countertop fabrication will be subbed out as will the painting of the entire basement. Today definitely felt like a major milestone in a project that has taken over a year to complete.

Inside Out

I have opted to seal the 8″ duct work for our ventilation system from the inside. Normally, sealant is applied on the outside seams but I think it results in a rather unattractive installation. I also chose to use rivets rather than sheet metal screws to secure sections of ducting. Screws, in my experience, can loosen up over time, something I have never seen with a properly set rivet. These details take extra time and no one will ever notice them. Creating innovative works of enduring value is one component of my personal mission statement. I think it is fair to say that my approach to ductwork falls under that banner.

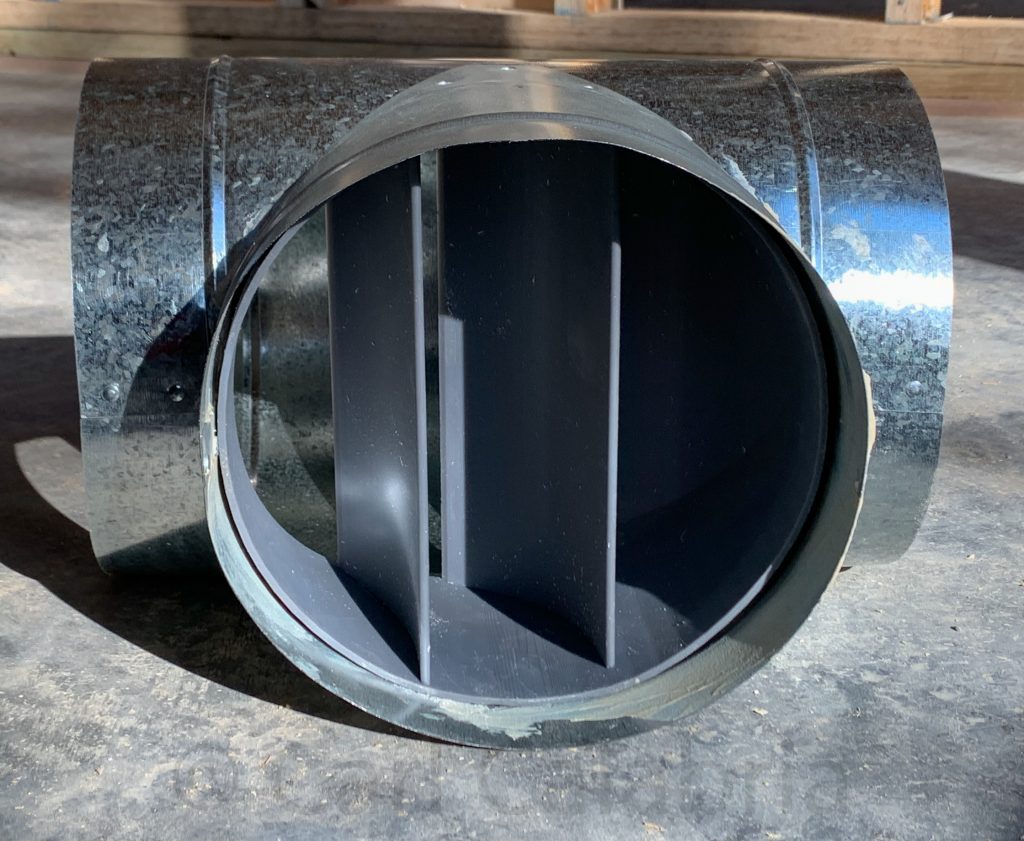

Custom Turning Vane

In order to optimize the routing of ductwork for the ventilation system in the River House, I found it advantageous to use a “T” junction to split airflow between two different circuits. A “Y” junction would have been optimal for this application but would result in far more complex duct routing at the expense of overall system performance. My solution was to design a set of internal turning vanes that will direct half of the air into each of the 8″ round ” T ” stubs. I sent Maya the CAD file and she printed the part for me on a Formlabs Form3L. The print took 24 hours and turned out beautifully (pun intended).

Vela

Maya is very conscientious of lab safety but may have taken things a bit too far with her favorite work dog, Vela.

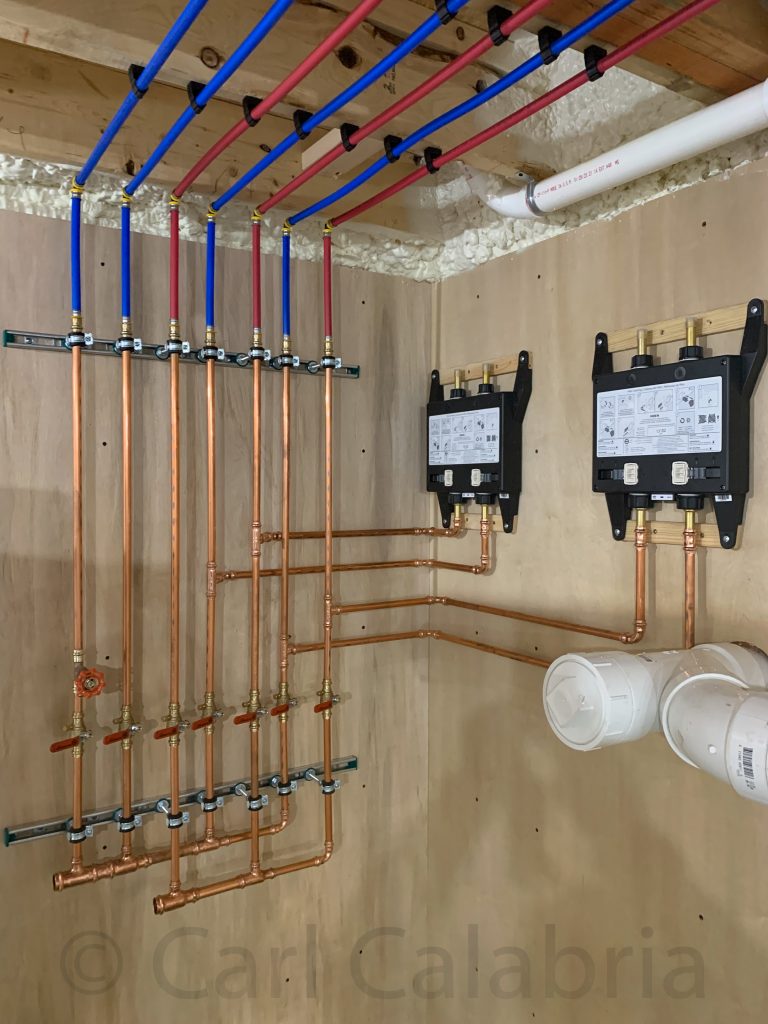

Pretty Pipes

Plumbing work on the new house has moved to the supply lines with all of the drain and vent work now completed. I could not be happier with the workmanship. The main and guest bedrooms will have digitally controlled valves. These are the two black boxes on the right. A console in each shower area will control the valves allowing for selection between a rain head and a shower head, precise temperature control, user presets, and integration with our home automation system. “Hey Siri, start Carl’s shower.” My preset temperature and shower head combination will be selected and when the water reaches the set temperature the shower will pause until I enter. This feature is a little bit decadent but there are few things that I covet more than the relaxation derived from my morning shower. It is where I do my best thinking and relieve the aches and pains that seem to be the new normal as my age advances.

The manifold on the left includes hot (red) and cold (blue) supply line shutoffs for different sections of the house. The valve on the far left is for the outside water bibs and includes a purge valve for winterization.

Solo Work Day

The threat of snowfall from a powerful Nor’easter kept all but the plumbers from showing up at the River House today and they only worked until mid-morning. This gave me free run of the house to complete the ventilation distribution system for which I am the installer. What I enjoyed most was the peace and quiet. The subs invariably have their job site radio’s tuned to stations I do not particularly care for. The snow kept mixing with rain throughout the day which limited total accumulation to about 3 inches. Had it been one to two degrees colder, we could have easily seen three times that amount.

Sharing the Chase

When designing the layout for the River House, I provisioned for a vertical chase behind the stairwell to accommodate the various mechanical systems of the house. It goes from the basement all the way to the roof line. At the time, I thought I had provided a generous amount of space. Now I am thankful that everything is just fitting (barely). The chase is occupied by the following items:

- 8″ round intake duct (ventilation system)

- 8″ round exhaust duct (ventilation system)

- 4″ radon vent

- 12″ x 8″ second floor heating/cooling supply duct

- 12″ x 8″ second floor return duct

- 10″ x 8″ first floor heating/cooling supply duct

- Eight 3″ round fresh air supply ducts

- Eight 3″ round stale air exhaust ducts

Key to fully utilizing the space has been the interactive staging of work. Today, I installed eight fresh air ducts (white tubes). Next, the HVAC contractor will complete the horizontal section of the supply duct. Then, I will run additional round ducts in the 2×4 bay on the near side. Any other order of work would preclude this degree of packing density.

Swedish Almond Torte

Jeanine prepared this Swedish almond torte for a dinner party we held this evening. Our guests included two couples with whom we have a great deal in common but have not thus far spent much time together. The company was wonderful and the food delicious. It made for a very relaxing evening after a second day of back-breaking work running ventilation tubes at the River House.

The Michelin Man

Kyle spent the entire day helping me install the ventilation tubes that will supply fresh air to the River House. In total, the project requires some 1500 feet of tubing. Kyle’s preferred method for carrying the 150-foot spools struck me as very amusing. By the end of the day, we completed 14 of the 32 runs from various parts of the house to the mechanical room where they will be connected to a Zehnder Comfoair Q600. Pulling these corrugated tubes through the joists and cutouts between floors is some of the most physically tiring work you can imagine. Every muscle in my body is sore from the effort and I imagine Kyle will be moving a little slowly tomorrow as well.