The first of two episodes on the Build Show featuring our River House project dropped today. In it, our architect, Steve Baczek discusses aspects of the design with host Matt Risinger.

Two Steps Backward, One Step Forward

Last week, FedEx attempted to deliver two pallets of plywood that I ordered weeks ago. The first pallet was as ordered. The second contained long boxes and not the 4’x8′ sheet goods I was expecting. I accepted the first pallet and rejected the second. Naturally, the missing plywood is what I need to complete the stair railings. The supplier acknowledged the error and is shipping out the correct material but it will probably take several weeks for that to arrive. Since our occupancy permit is gated by the completion of the stair railing, I have opted to proceed using scrap plywood that I will later replace with bamboo. This morning, I built and installed 7 temporary newell posts (three visible in the photo, the remainder are on the floors above and below). I then installed all the balusters for the guard rails on a spacer rail that will hold them in the correct position until I can epoxy them to the lag screw studs in the floor. Once cured, I will replace the spacer rail with a temporary code compliant railing. Next, I will repeat the process for the stair hand rails. On a positive note, I really like the shadow pattern generated by the balusters.

Nico’s AdaptX Podcast

Nico was recently featured in an AdaptX podcast interview. The extensive conversation is centered on the work he is doing with the Bionic Project as well as his crusade to build a world-class amputee soccer program in the US. I am extremely proud of the work he is doing and how eloquently he speaks about it. If you can set aside an hour to listen to the full interview, I promise you will learn some things that will change your perspective regarding people with a disability.

Decapitation

With the holidays in the rearview mirror, it was time to get back to work on the River House. I used an abrasive cutoff disc in my grinder to remove the heads of ~150 half-inch lag screws. It was not a pleasant task. I had to wear a respirator, protective goggles, and hearing protection for my safety and used the galvanized steel jig below to protect the stairs and floors from the spark generated by the grinding process. It took me about a minute to decapitate each screw which translates to about 2 1/2 hours bent over with a heavy grinder. Jeanine was kind enough to give me a back rub that helped alleviate the pain. I also began to erect the temporary scaffolding that will hold the balusters in place while they are glued to the studs on the floor.

Brisketeer

Last night, Jeanine and I spent New Year’s Eve with Kyle and his girlfriend Heloisa at the River House. We spent a good deal of time outside before and after dinner gathered around our new fire pit for its inaugural use. Kyle prepared a smoked brisket which we had for dinner and a second time today when the boys came over to watch Premier League Soccer (Liverpool vs Manchester United) on the big screen. Kyle is well on his way to becoming a grill master and we are fortunate to be the beneficiaries of his growing passion for the art.

Step and Repeat

It is fitting that on this last day of a year full of construction, I would be working on the last project standing in the way of getting our occupancy permit for the new house. The railing system for our stairs will use three vertical balusters per stair tread. These hollow steel tubes will be epoxied to the lag screws which I installed today but not until after I cut the heads off. I have opted for epoxy over an earlier idea I had since it will be stronger and offer more latitude for adjusting perpendicularity. In total, I installed just shy of 150 screws. Each one had to be perfectly positioned and driven in plumb. To accomplish this I built several jigs to ensure repeatability and accuracy.

Answer to yesterday’s puzzle: The bird sitting on the top shelf to the right of center.

Puzzle

Kitchen Complete!

Located at the back of the River House walk-in pantry is a column-style freezer that until today lacked a matching bamboo panel for the door. It was the last component needed to 100% complete the kitchen. Even though Jeanine originally wanted a push-to-open capability for the refrigerator and freezer she has since decided she would prefer a traditional handle and requested that it be made of bamboo to match everything else. Her wish was my command.

Masterpiece

I rarely, if ever, post photographs that are not mine or ones taken by family members. Today, I encountered an image that was so perfectly executed that I felt compelled to share it. I was not able to ascertain the photographer but it was originally posted on a yoga studio Instagram page. Kudos to the photographer and model. Perhaps, my interest in this photo is a sign that I am ready for a beach vacation after months of work on the new house. I am confident it is not a sign that I should take up yoga any time soon.

Finishers at Work

After more than 2 months of waiting, the additional bamboo plywood needed to continue built-in construction at the River House finally arrived. I cut all the panels needed to complete the drawer fronts and cabinet doors for the laundry, mudroom, and shop and the front panel for the flush-mounted freezer in the pantry. Jeanine and Susan worked together to apply finish to some two dozen panels leaving them ready for installation. I also started replacing the temporary stairs from the back hall to the garage with the final design that includes provisions for a future wheelchair ramp should that ever be needed. An additional shipment of plywood for the indoor stair railing is scheduled to arrive tomorrow, weather permitting. With any luck, we will be ready for our occupancy inspection during the first week of the new year.

Secret Santa

For many years now we have been doing a Secret Santa gift exchange. Everyone in our immediate family group is randomly and secretly assigned someone else in the group for whom to purchase a gift(s). Rather than shopping for everyone in the family, you only need to focus on one person. This year, Nico was my Secret Santa and he got me a super sweet Arctyrex jacket among other smaller items. Since I have been an exceptionally good boy this year, I decided that I would also give myself a gift. When I saw this miter gauge go on sale for 50% off I could not resist the temptation. When it arrived the day before Christmas, I decided to leave it in the box and put it under the tree with a Secret Santa label addressed to me. It took the family about 2 seconds to figure out what was going on. It is said that it is better to give than to receive. I am prepared to assert that it is even more satisfying to do both at the same time.

Swans a’ Swimming

Jeanine and I spent the night sleeping at the River House so that there would be enough beds at the Road House for all the guests we have this year. We woke up to fog on the river and swans swimming downstream. Even though there were only four of the famed 7 swans a’ swimming, it felt like a true blessing.

Christmas Crew

Fiona, one of Maya’s roommates and high school friend is staying with us over the Christmas holiday. Work prevented her from joining her parents who are celebrating in England. Also visiting us is Jeanine’s sister, Susan who we always look forward to spending the holidays with. This evening we gathered at the River House where we enjoyed raclette, a Swiss dish, also popular in other Alpine countries, based on heating cheese and scraping off the melted part onto boiled potatoes and sausages. Maya created a Bouche de Noël for dessert complete with woodland decorations (my favorite are the mushrooms). We also enjoyed fine chocolates, a gift from Nicolai’s girlfriend Samantha and her dog.

Chef Quinn

I have never thought of my sister Alissa as much of a cook. Recently, however, she has become much more adventurous in the kitchen and I am considering updating my assessment of her culinary talents. However, such will not be done until I have had a chance to sample the goods. Hint: This could be facilitated by a small overnight care package.

Temporary Railings

Before we can get our certificate of occupancy for the River House, we need to have stair railings, final or temporary in place for the interior and exterior stairs. Today I completed temporary railings for the front door steps and patio steps. These will eventually be fabricated in stainless steel, work best done in warm weather, and after the steps have had plenty of time to settle into their final positions. I was able to secure the front stair railings into the stone using anchor bolts which will not be visible when they are eventually removed. For the patio stairs, I chose to use 5-gallon pails filled with 100 pounds of concrete for bases rather than drilling holes which will be visible later.

Year End Practice / Party

Jeanine, Maya, Samantha, and I attended the end-of-the-year party/amputee soccer clinic/Amputee Revs soccer practice this evening in Marlborough. Children were given an opportunity to play soccer on crutches to gain an appreciation for the challenges faced by those with limb differences. They did warmup drills followed by a match. Eventually, those who did not need them, shed their crutches and play morphed into a practice session for Nico’s soccer team.

Finally, A Solution

It has taken the better part of two weeks, but I have finally devised a satisfactory method for affixing the stair balusters to the stair treads at the River House. I purchased 150 round 5/8″ diameter hollow metal tubes to fashion the balusters. When they arrived, I discovered they were neither 5/8″ in diameter nor truly round both of which I was counting on to mount them using my original concept. Since then, I have experimented with several different approaches but none provided the lateral stiffness I am looking for. Today, I finally arrived at a robust and cost-effective solution. I predrill and drive a 1/2″ lag screw into the stair tread using a jig to make sure it is normal to the plane of the tread. Next, I cut off the hex head of the screw. Then, I fashion a short piece of 14 gauge wire into the shape shown in the photo and place it over the screw shaft. Finally, I drive the hollow tube over the assembly. This creates an interference fit along three lines (one on each wire and the third on the opposite side of the screw shaft). When I tested the connection it was as if I had set the baluster in concrete.

New Tradition

Normally, the family makes Zeppole Balls on Christmas Eve. This year the kids elected to do so early allowing their significant others to join us before heading home to spend the holidays with family. Nicolai appointed himself Captain Christmas, procured a perfect-sized tree, and directed activities for the evening. These included trimming the tree, making the Zeppole, eating the Zeppole, and watching the movie Klaus.

Near Miss

This morning, a fierce storm passed through our neighborhood with 70mph winds and intense rain. We had five trees come down at the River House, one across the driveway and one just missing our garage. Our neighbors to the south were less fortunate. A tree came down on their sunroom for the second time in five years. Mercifully, no one was hurt even though they were in an adjacent room at the time. Within minutes, a dozen neighbors showed up to render assistance. I used my chainsaw to help remove limbs and we eventually cleared all but the main trunk. Working on a ladder inside the house, I was able to section and remove the large limb resting on the roof clearing the way for a temporary tarp. Another neighbor had a tree blocking their walkway and I was happy to clear that as well. I have a full day of consulting tomorrow and plan to spend most of Wednesday clearing our yard.

Holiday Lights

Kyle decided to install LED lighting under the eves of his house and can be seen in this photo working his way around the roofline. He does appear to be exercising caution but I will admit to being worried all day when I learned of this project. Each year, there are more than 164,000 emergency room-treated injuries and 300 deaths in the U.S. that are caused by falls from ladders. He completed the work successfully and sent around the video below.

Initial Prototypes

Maya spent the day at the Road House repairing her tiny house. It will never be as good as new, but it is starting to look respectable again. She also delivered some 3D-printed prototypes I designed to anchor the stair railing balusters. A long screw is used to secure these columns to the stair tread and the hollow steel baluster is slid down over it. The ribs are necessary because the tubes are not perfectly circular and are not uniformly consistent in size. Unfortunately, a quick test revealed that this attachment method will not provide the degree of lateral support I was hoping for. I may still use this approach but will have to design a more substantial Newell post to provide the needed strength for the assembly.

Suboptimal Perspective

I think that most homes, like most faces, have a best side for photography. When we designed the River House, we wanted to take maximum advantage of the views of the water. A good 80% of the windows are on the river-facing side and hence most of the facade’s interest and character. We knew this would mean that the “front” of our house would be rather bland by comparison. What we did not count on, is that trees would make it impossible to capture a decent photo of the house from its best angle. The photo above is the best I could do with my drone. Ideally, it should have been taken from 30 feet further back and 10 degrees to the right. Alas, that photo will never exist. I will, however, be reshooting this in better light when I get a chance.

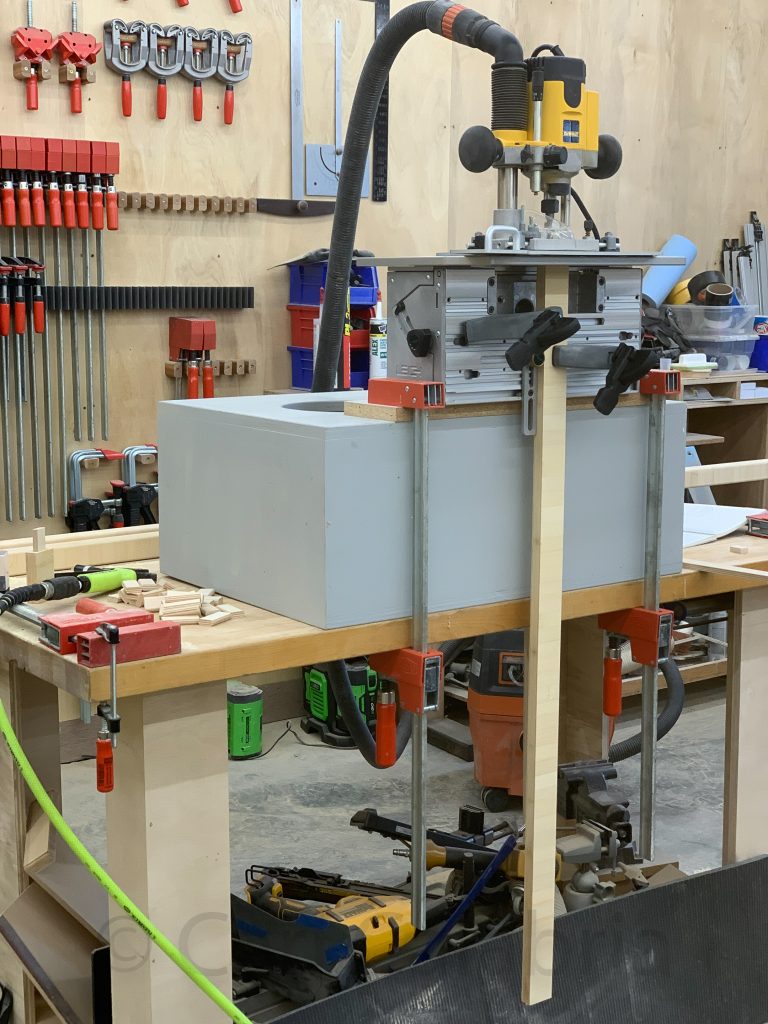

Mortise and Floating Tenon

After testing the first stair railing I built earlier this week, I have decided that the butt joints need to be strengthened with a mortise and floating tenon joint. Even though these butt joints overlap and are glued to a continuous sistered section of plywood, they are not as stiff as I would like them to be. I fabricated the tenons from 3/8″ baltic birch plywood and made the mortises with a jig I have for this purpose. I glued up a couple of 9-foot sections and will test their strength tomorrow morning. I also completed the design for a 3D printable connector that will anchor the hollow steel tube balusters to the stair treads and the handrail.

The Book Club Inagural

Jeanine hosted her book club at the River House this evening. It was the first official gathering at the new house and it was also special because the book was “A Taste of Stories,” Jeanine’s cookbook memoir. Everyone came with dishes prepared from recipes in the book and Jeanine did a reading for the group. I cannot think of a better inauguration.

The Build Show

This morning we had a distinguished group of visitors at the River House. Our architect Steve Baczek (blue jeans) invited Matt Risinger (thumbs up) of the Build Show fame and his team for a tour. It turns out that Matt’s first passion is photography, something we have in common. I enjoyed our conversation which ranged from camera systems to magnetic door latches. Matt and Steve have done more to share building science knowledge with the world than anyone I know. I spent dozens of hours watching their online videos when I was doing research for our build. After giving them a full tour of the house, they went back to shoot several video segments on the features that they thought would be of most interest to their audience. I will post links when they are published.

Matt had some very nice things to say about our new home and coming from someone who has probably toured hundreds if not thousands of houses, felt like high praise indeed.

Accessorizing

The kitchen sink in our new house is just shy of 4 feet long. It features dual ledges that accept sliding accessories. Jeanine and I visited the website where we purchased the sink and she identified the most useful add-ons. Rather than shell out +$400 for these items, I made them all and then some for less than $75. For the top ledge, I built two bamboo chopping boards (one long grain and one butcher block style end grain) and a high-density plastic chopping board. For the lower ledge, I purchased a roll-up drying shelf ($7) and a collander/bowl combination ($22) which I fit into a second high density plastic frame ($23). Also pictured above at the back are two thick bamboo butcher block cutting boards I fashioned from wood scraps I generated while building the kitchen cabinets.

Handrails

I got started fabricating the handrails we will use for the stairs at the River House. I am using the same bamboo that I used for the stair treads for a perfect match. This requires that I laminate pieces together to get the desired size rail. Pictured above is a 12-foot rail made of 6 staggered and overlapped 4-foot sections.

Bollards

To obtain fire department approval for our backup batteries we were required to add a pair of safety bollards to protect them from potential mechanical damage (presumably from a wayward car). The project required less than 30 minutes to complete but only after an entire morning of clearing out that side of the garage. Next, we need to move the breaker box shown above the batteries about 5 feet to the right to meet the electrical code. I will spare you a tirade on why this makes no sense but if I have learned one thing while building this house it is that building codes trump common sense every time.

On the Mend

For the second weekend in a row, Maya stopped by to repair her tiny house which sustained major damage when a large tree limb fell on it. By the end of the day, she had addressed all of the structural damage. To further strengthen the structure, she added two columns to the previously cantilevered porch loft. Maya joined us for dinner and then baked cookies with Jeanine. I was not allowed to sample any of them.

A Bit of Organizing

I have been so busy building cabinets and stairs for the River House that my shop has gotten quite cluttered with off-cut bamboo plywood. At nearly $10/sqft. I am reluctant to throw away even the smallest piece. Truth be told, I would not throw it out even if it were free. I just can’t bear throwing away anything that has intrinsic value. Thus far these off-cuts have been randomly stacked against my shop wall making it very time-consuming to find a particular scrap of the right size and grain orientation. Today, I did a bit of shop organization while our painters put the finishing touches on our stairwell, the one area they were unable to complete until the new stairs were installed.

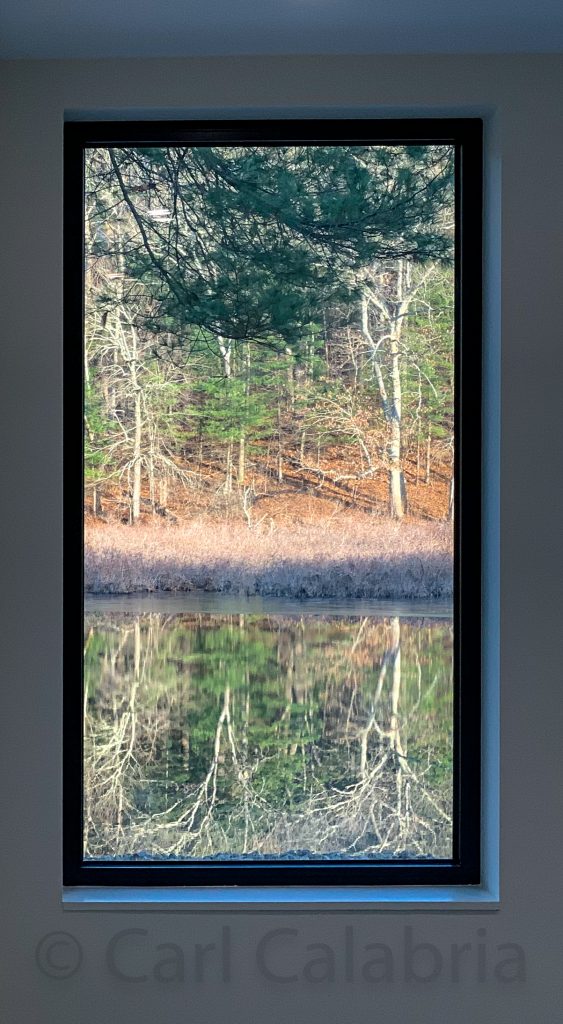

Picture Window

Visitors entering the River House often comment that they feel like they have just stepped onto a boat. The first-floor elevation provides a perspective that makes you feel like you are on the water. By contrast, the view from the basement provides an eye-level view of the river. A recent guest commented that this was the first picture window he had seen that truly looked like a picture.