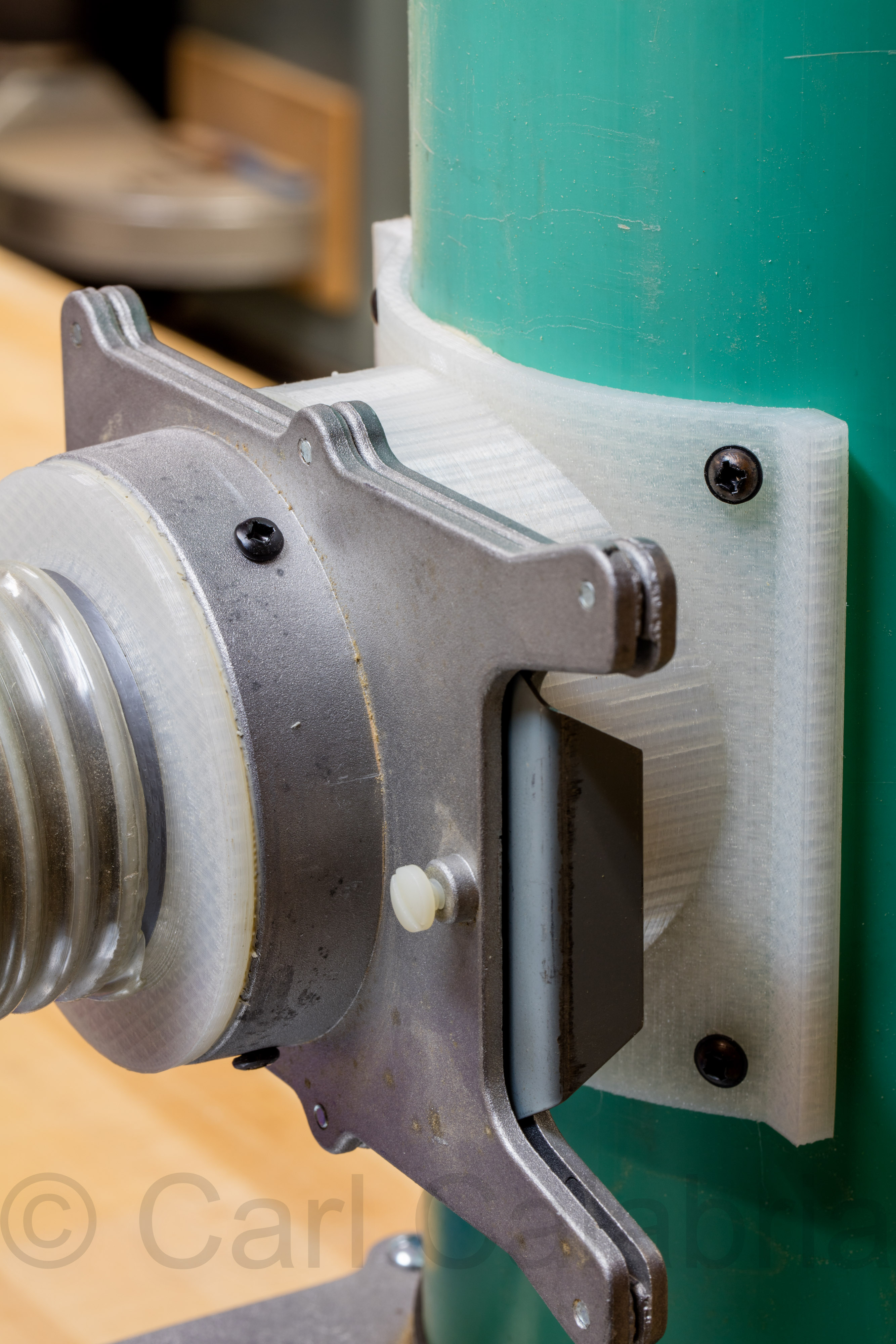

When I designed the dust collection system for my shop I ensured that every major piece of dust-producing equipment had a dedicated drop. The one thing I forgot to provision for was a simple vacuum hose. Why not use my 3hp cyclonic vacuum with 55-gallon bin capacity instead of my 6-gallon shop vac with expensive bags for general clean up. In order to make this happen I had to tap into an existing 8″ drop that services my table saw. Normally this would involve a lot of shopping around and cobbling together the right combination of pipes and flanges. With access to a 3D printer, however, the entire project was a breeze. It took 20 minutes to CAD a flange that would mate perfectly with the 4″ blast gate I use to control airflow. I also designed a step-down adapter to interface the blast gate with my 2 1/2″ vacuum hose. It took less than ten minutes to cut a hole in the existing pipe and install the components. The new vacuum line works perfectly with no air leaks and could suck the underwear off a nun.