Kyle has graduated from apprentice to novice carpenter. He created this video to document his first major solo woodworking project. With new tenants about to rent his newly renovated basement, he decided to add much-needed storage to his garage in the form of 2-foot-deep shelves. It fills me with great joy to see him using the skills he developed while we worked together on the renovation.

Monthly Archives: June 2023

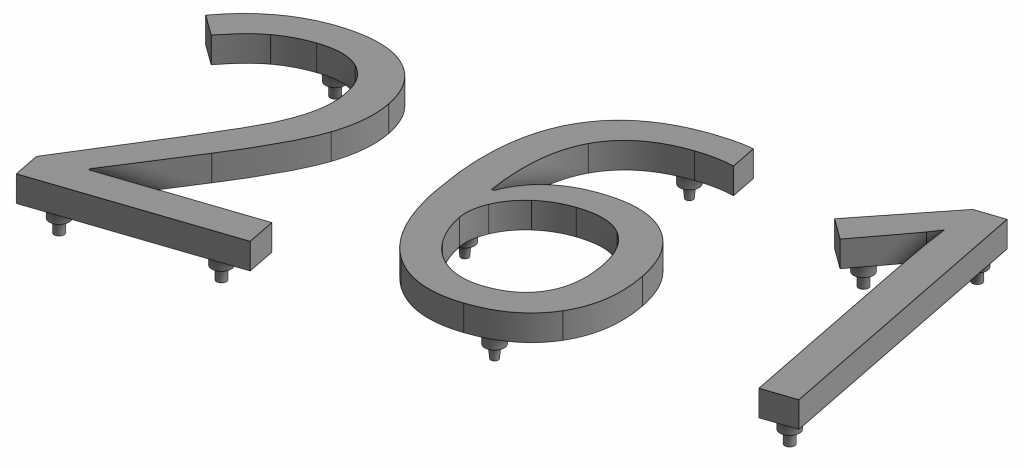

House Numbers

Jeanine joined me at the River House to check out the build progress. We used the opportunity to model what our house number will look like at scale. Maya 3D printed these numbers for us at work and even though I could not hold them up with the proper spacing, we are very pleased with the size. Initially, we thought we would buy backlit numbers and I provisioned for the power to do this. Upon further reflection, however, I think we have decided that we would prefer not to illuminate the numbers. Visitors looking for our house at night will be more likely to rely on the reflective numbers on our mailbox than peering through the 300 feet deep forest of trees separating our house from the road.

Turtlecide

Last weekend I ran over a turtle with my car when I arrived at the River House to work. It would appear to be a female snapping turtle and measured about 7 inches in length. I did not see the turtle nor did I realize I had driven over it. I only noticed it when I got out of my car and immediately felt sick to my stomach, not at the sight, but because I had caused the death of this wonderful creature. I suspect the turtle had come from the river in search of a place to bury her eggs. This only compounded my feelings of guilt. By the time I had completed my work for the day, all that remained of the turtle was its shell. I take a small measure of consolation knowing that the other wildlife we share our yard with gained nourishment from this tragedy. Over the course of my life, I have helped to save a handful of wayward turtles. I hope this history of compassion and care will help me to forgive myself.

The Cutting Edge

My new jointer planer has 5 rows of 15mm x 15mm x 2.5mm square four-sided convex edge carbide knives for a total of 80 knives. When an edge of a knife gets dull or damaged you simply remove the locking screw and rotate the knife to a new edge. The helical arrangement of the blades results in a smoother cut and less tear-out on difficult grain. I spent some time doing the final tuning of the infeed and outfeed tables today as well as sealing all the joints on my dust collection system.

Open For Business

While it is far from complete, my new wood shop at the River House is officially open for business. As of today, all of my major machines are operational and I have access to most of my tools and building supplies. The automatic dust collection system is up and running on my table saw, jointer/planer, and bandsaw. Jeanine stopped by to see the garage doors that were installed today and found me working in my shop for this photo. Just ten days ago, this was an empty room and now I am ready to start building cabinetry for the house.

Boston Unity Cup

Nicolai returned to the soccer pitch this afternoon playing in a showcase match to kick off the month-long Boston Unity Cup. He played with and against many of his teammates from the US national team as well as several exciting new players who have recently joined the sport. The tournament is meant to reimagine the power of soccer to build community, connect people from diverse backgrounds, and promote equity. Nico had 2 goals and 2 assists in a tight 4-3 win. Photos from the match can be found here.

Consolidation

I spent the morning moving tons (literally) of shop supplies and hardware from the detached garage where it has been stored for the last two and a half years into the new house’s basement. A constant light rain only added to the drudgery of the task. Currently, the mechanical room and shop are the only two rooms that are ready for occupancy, all others have yet to be painted. As I have yet to create any permanent storage solutions in the shop it is getting quite crowded so I opted to temporarily store much of what I moved in the mechanical room.

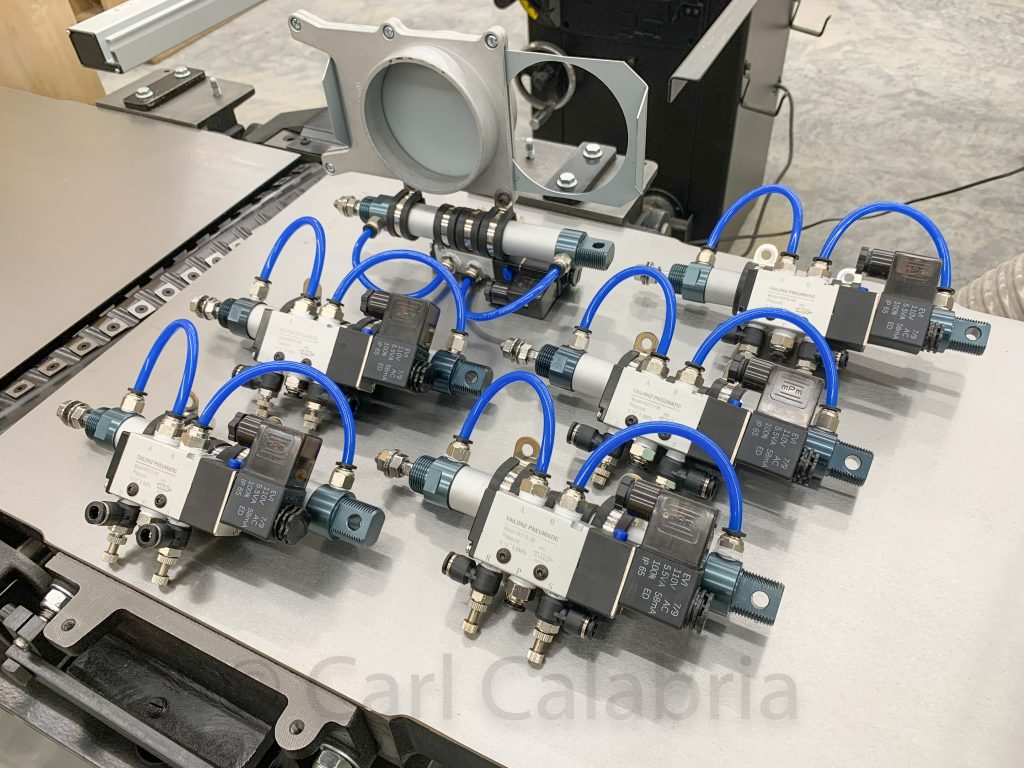

Having successfully tested my first pneumatic blast gate earlier in the week, I moved on to the assembly and testing of the remaining units during the afternoon. I still have to fabricate and attach the arm that connects the pneumatic cylinder’s piston to the blast gate.

Having a Blast

The dust collector in a wood shop is a shared resource. In the simplest systems, you connect a single hose to whichever machine you happen to be using. This stops being fun on your first project. The next step up incorporates an array of ducts that connect all machines to the dust collector. This requires “blast gates” at each machine so that only the one being operated is open thus maximizing air flow. This is what I have used in all my previous shops. Whenever you move to a new machine, you close the blast gate of the last machine and open the blast gate of the next machine. Over the years, this too becomes tiresome. The ultimate solution is an automated system that detects which machine you are using and opens only the blast gate connected to it and turns on the dust collector. A couple of years ago, I design such a gate fashioned from an off the shelf blast gate coupled to a pneumatic actuator and control valve. This afternoon, I connected the first of seven to my bandsaw. Open and close times are fully adjustable. I plan to slow the close enough to allow the dust collector to clear the ducts before shutting down.

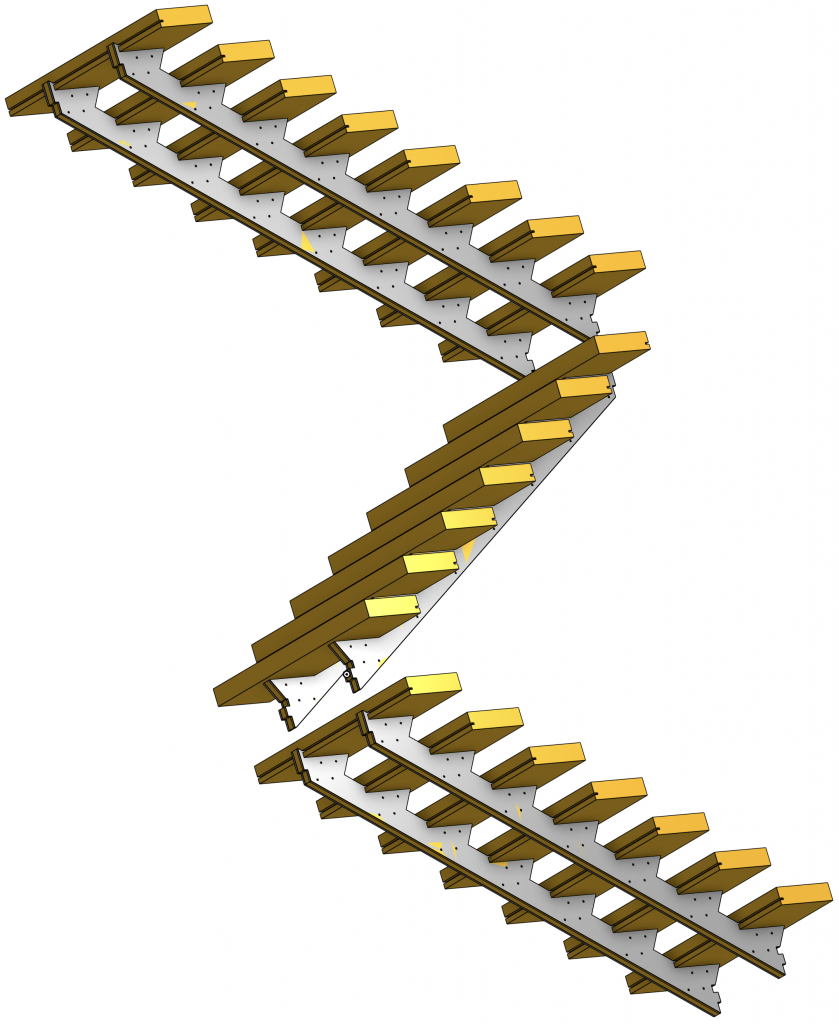

Moving Heavy Things Day

For the second time this week, I rented a trailer from U-Haul. This time it was to pick up 780 pounds of laser-cut steel stair stringers that we will be using in the River House. Pictured above is a photo from earlier this month depicting my final design. Below are the fabricated stringers loaded onto a utility trailer. On and offloading these was quite a good workout with each of the twelve averaging 65 pounds.

As if I needed more exercise, I decided that today was the day to move my very heavy jointer/planer from the garage into my shop. The ground was relatively dry and weather predictions are calling for on-and-off rain for the next several days. Using a bunch of blocks and levers, I single-handedly got the machine off its shipping pallet and onto the dolly I built yesterday. I was grateful that Kyle was able to join me after he finished work to assist with the difficult task of getting it down to the basement level and up a home-built ramp onto the shop floor.

Two Ton Dolly

I have decided that the best way to move my nearly 600-pound jointer/planer from the garage where it is currently stored into the shop is with a dolly and a couple of strong helpers. I looked at purchasing one but was put off by the price. Cheap ones with a 2x safety factor are around $300 and from their appearance do not seem up to the task. Really well-designed ones are almost twice that much. I decided to pick up a set of swivel casters rated for an 1100-pound load each ($60 for the set) and built the base out of left-over framing lumber. The wheels are 4 inches tall and 2 inches wide. I plan to use scrap sheets of OSB for a smooth surface over which to roll the loaded dolly. Only time will tell if this plan works out. Of one thing I am certain. This dolly will definitely stand up to the load.

Side Note: My shop is now largely operational. I used my miter saw, table saw, bandsaw, and planer in the construction of this project which features lap joints at the corners.

Huevos Rancheros

Downlights

Our house builder has been making slow and steady progress on the soffits. They are using a man lift to position themselves under the eves to facilitate the work. Before moving it to a new section of the roof, I hitched a ride to install the downlights that will illuminate a future patio. Beats the hell out of a ladder.

Nephew Visit

We enjoyed a visit today from our nephew, John Quinn. He met us at the River House for an extended tour followed by a late lunch in West Concord. It was great to catch up with him and learn about his plans for the future.

I spent the balance of the day moving into and beginning to organize my new shop. Tomorrow, I plan to install provisional dust collection and will be very nearly ready to start cabinet making once the bamboo plywood I ordered arrives.

Strawberry Festival

Today, we celebrated both Father’s Day and Maya’s birthday, one and two days early respectively. We attended the Verrill Farm Strawberry Festival in the morning and were fortunate to miss the rain that fell for much of the rest of the day. Jeanine suggested the event and I thought it would be great fun. After noticing the very large number of small children in attendance, Kyle suggested this was a planned attempt to accelerate the timetable for having grandchildren. No such subterfuge was at play but if it had that effect, I will be choosing to attend the festival again next year. I feel very fortunate that the kids all live close by and that we can be together so often.

In the afternoon, Kyle helped me to collect a three-piece recliner that will go in the mini-theater of our new house. While we had the U-Haul trailer we also returned the recliner that Jeanine has been using while recovering from her foot surgery and moved a bunch of shop equipment from the Road House basement to the River House.

Let There Be Light

This morning, I installed lighting for my new shop. The setup includes 7 rows of 20-foot-long linear LED lamps. Each 20-foot section is made up of five 4-foot-long sections (four rows are visible in the photo). The total light output is 75,000 lumens. The arrangement provides shadow-free very bright illumination over the entire shop. When full brightness is not required, only half the lights can be turned on but still cover the entire floor space.

In the afternoon, I moved my table saw and bandsaw from the garage into the shop. I managed the effort single handed but will need help with the jointer/planer which weighs twice as much at 572 pounds. Once I lock in the location of each machine, I will connect each to my dust collection system and will declare my shop open for business. That business will include making all the kitchen cabinets and vanities for all the bathrooms.

4 Weeks and Crutching

It has been 4 weeks since Jeanine had foot surgery to correct a previously botched bunion procedure. Her doctor has given her the all-clear to start putting up to 50% of her weight on the foot. Although her knee scooter is still the most comfortable way to move around, the process of loading and unloading it from the car has kept her from driving anywhere. Now that she is up on crutches, she is back on the road again.

Prickly Encounter

The beauty of nature never ceases to amaze me. I found this cactus growing inside a large pot outside a U-Haul rental center of all places. The responsible gardener notice me taking a picture and was happy to explain how he had found one little stem years ago and had been dividing them ever since. The photo only shows a few of the several hundred that now completely fill the 30-inch-wide pot. Stopping to smell the roses might be fine for people whose dominant sense is olfactory. For someone who is more visually oriented, I find it more satisfying to pause and look at the cacti.

The Heavy Weight Champ

The 16″ jointer/planer I ordered arrived today. At 572 pounds (660 pounds as shown) it is the heaviest thing that will reside in our new house. I am still contemplating the best approach to getting it from the carport where it now sits into my shop. The motorized pallet jack that brought it down the driveway is only good on hard surfaces and would have sunk in the rain-soaked clay soil had we tried to get any closer to the house. I will probably uncrate it and disassemble it into lighter components (motor, beds, cutter head, fence). The extra work will be worth the riskier challenge of moving such a heavy object. You can count on a blog post once it reaches its final resting place.

Pressing Matter

The last essential system I need to set up before getting down to business in my new shop is dust collection. The dust collector has already been installed in the mechanical room along with ducting into the shop. Now I need to connect the duct work in the shop to the various machines. I decided to make the duct supports out of leftover plywood. A long cable tie will be used to secure the pipe to the support and the support will be anchored to the wall with pocket hole screws. The cable tie will run through a hole bored through the full width of the 3/4 inch thick support. To make that hole I needed to set up my new drill press. It went together without a hitch and has exceeded my expectations for build quality and accuracy. It was a real pleasure to use.

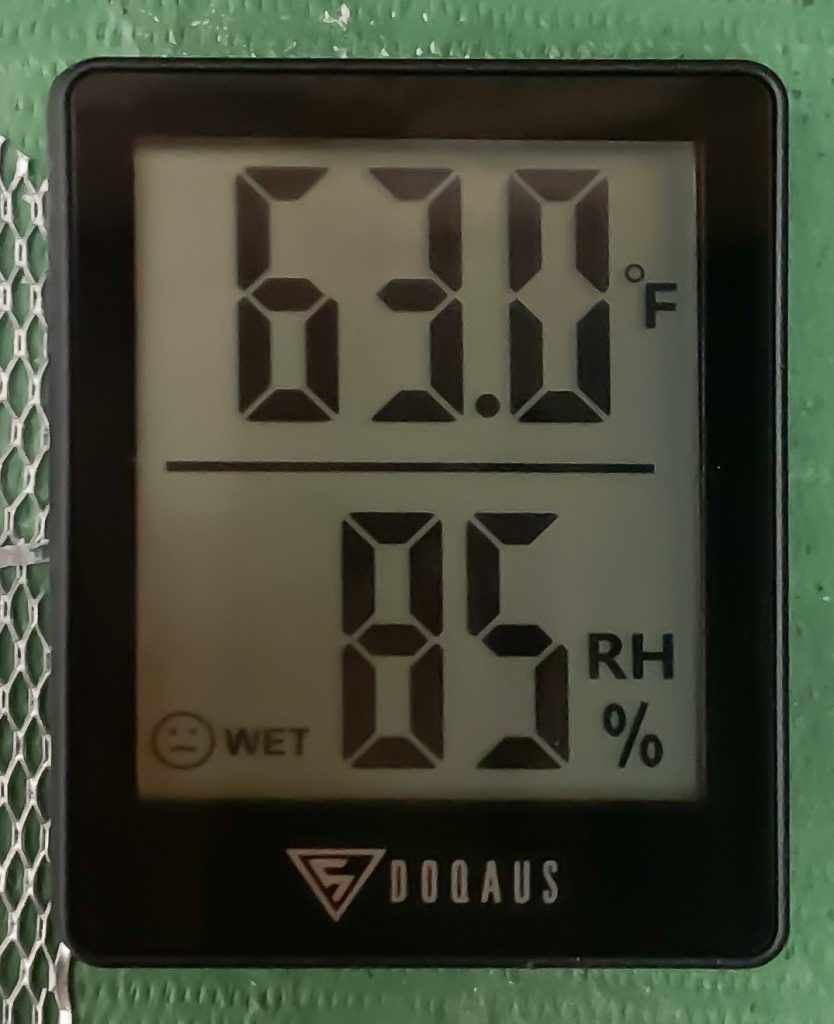

Very Wet

Plaster work on the River House should be completed this week and will be followed by wood flooring installation but not before the indoor humidity reaches an acceptable level. I installed a digital hygrometer on each floor to monitor humidity levels. At this time it is hovering around 85% and the current and forecasted weather is not going to help much. I am going to look at renting an industrial dehumidifier to help speed things along.

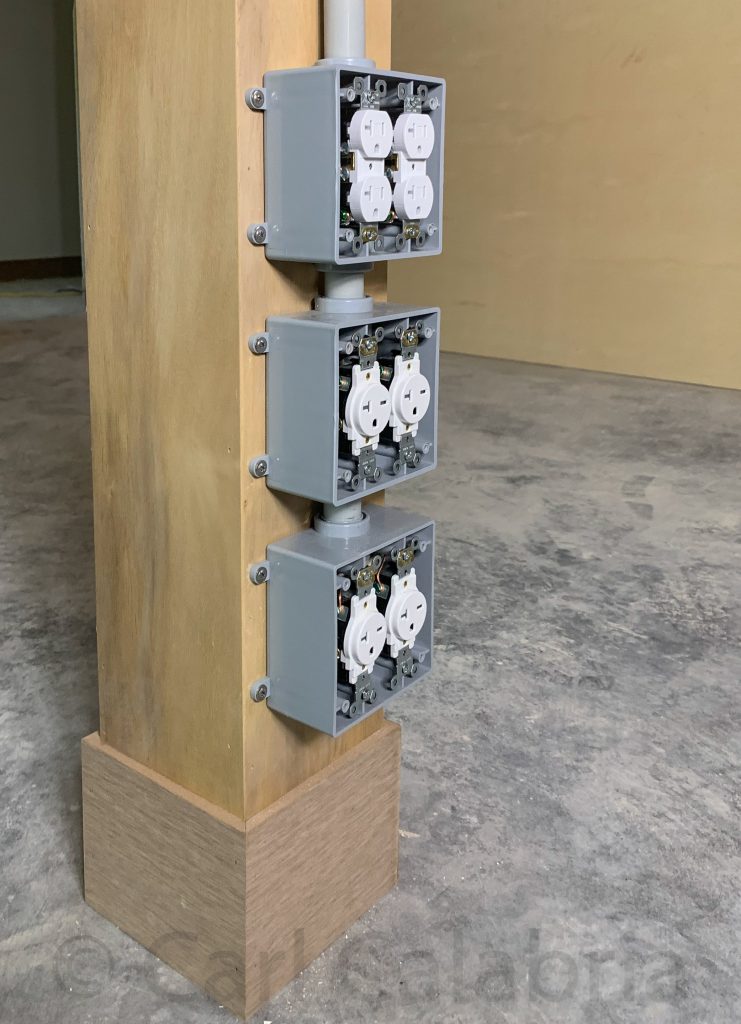

Power to Spare

My new shop at the River House has a single lally column located in the middle. Initially, I thought this would be highly undesirable. When I laid out my shop equipment, however, it became apparent that this would be the perfect means for dropping power to the machines which will be centrally located. Today, I built a square column around the round one and installed four 120V outlets and four 240V outlets upon it which will be used to power my table saw, bandsaw, jointer/planar, and router table with several spares. The base of the column and floor molding through the basement is built out of a rice hull-based product that is impervious to water. Should the basement ever flood, we can sustain 5-1/2″ of water before the drywall or plywood becomes exposed.

Freak Hail

For 15 minutes this afternoon, 3/8″ hail fell in Concord combined with torrential rain. At the time, I was parked under a tree which help minimize the impact of the ice chunks hitting my car. Driving was briefly treacherous on the frozen ball bearings but they melted quickly leaving little more than dismay behind. Hail in June where we live is a pretty good validation of climate change.

Boxed In

All that remains to be done before I can move into my new shop is the painting of the ceiling. This can happen in a few more days when the plaster has completely dried. In the meantime, I am taking care of a few construction details. Pictured above is an “L” shaped box I built to protect the geothermal water lines which run from that foundation wall to the mechanical room. The red light shown dangling in the upper left-hand corner is used to signal when my dust collector bin is full. It will get affixed to the wall or ceiling once the painting has been completed.

Northern Forest Canoe Trail

The NFCT extends for 740 miles across contiguous rivers, streams, and lakes, following Native American travel routes from Old Forge, New York, through Vermont, Québec, and New Hampshire, to Fort Kent, Maine. In addition to being a paddling route, the Trail celebrates the history of the Northern Forest. The Trail was officially completed in Spring 2006, with thirteen mapped contiguous sections offering campsites, portage routes, trail signs, and access points along the entire route. This photo taken near the western terminus was shared by my nephew, Gabriel, who is paddling a portion of the trail with his girlfriend. I don’t know all the details of the trip but I believe he will be meeting up with my sister-in-law Susan when they reach North Hero, VT which is 170 miles into the journey.

Purple Invader

Purple Loosestrife is a hardy, aggressive, non-native wetland invader. This herbaceous, ornamental perennial was first documented in the 19th century and it is likely purple Loosestrife was introduced either accidentally in ship ballast water or intentionally as a colorful garden ornamental. While it may not be a welcomed addition to the native ecosystem, it does make for a very attractive photography subject. I passed this field every day on my work commute for the last 18 years and have watched the Loosestrife continue to expand its footprint.

CMLP – The Best

Concord has its own municipal power and light company, unlike most towns and cities in Massachusetts. Followers of this blog may recall my rants about the abysmally slow and poor service provided by most of the utilities that have served us in the past; Verizon (phone), Comcast (TV and internet), and National Grid (gas). With the Concord Municipal Light Plant, the story could not be more different; they provide the best service of any utility we have ever used by a country mile. Today, they proactively installed a new utility pole having determined the old one was approaching its end of life. In response to a request I made while talking to them a few weeks ago, they relocated the new pole far from the corner of the driveway where the old one obstructed access, especially for larger vehicles. The new pole is pictured at the back of the truck on the right and the old one next to the traffic cone. With the new pole location established, we can now begin the work necessary to bury our electrical, water, and other utilities. The old pole will eventually be removed when the telephone company eventually gets around to moving their wires to the new one. I won’t be holding my breath waiting for this to happen.

Belldinni Doors

It has taken months and months for Jeanine and me to find interior doors for the new house. Door installation is scheduled to start in a few weeks, and the deadline has helped us make a decision. Pictured here are the doors that will be used for the bedrooms and offices. A plain slab version from the same collection will be used for the bathrooms, closets, and in the basement. We have specified concealed hinges and European-style magnetic door latches (no strike plates or protruding latch bolts). Still remaining to be selected is the bypass closet door in one bedroom and the fire-rated door between the house and garage.

Mooo

Every day, I make the 2-mile commute from the Road House to the River House to check on progress and perform work, often multiple times per day. On each trip, I pass a lovely field where about a dozen cows hang out and graze. These are perhaps the happiest and healthiest cows I have ever seen. I have enjoyed watching them grow over the last two years and will be sad when they are replaced. I stopped by to say hello and grab some photos this afternoon. I needed a break from kitchen cabinet design which I have been working on for the last few days.

By The Numbers

Jeanine had a clever idea for creating an indented area on the River House siding in which to display our street number. After looking through the low-quality or ridiculously expensive off-the-shelf options, I decided to design them myself and have asked Maya to print them at Formlabs on one of their large format 3D printers. Each digit is 12″ tall and 1″ thick with an integrated standoff and fastening stud.

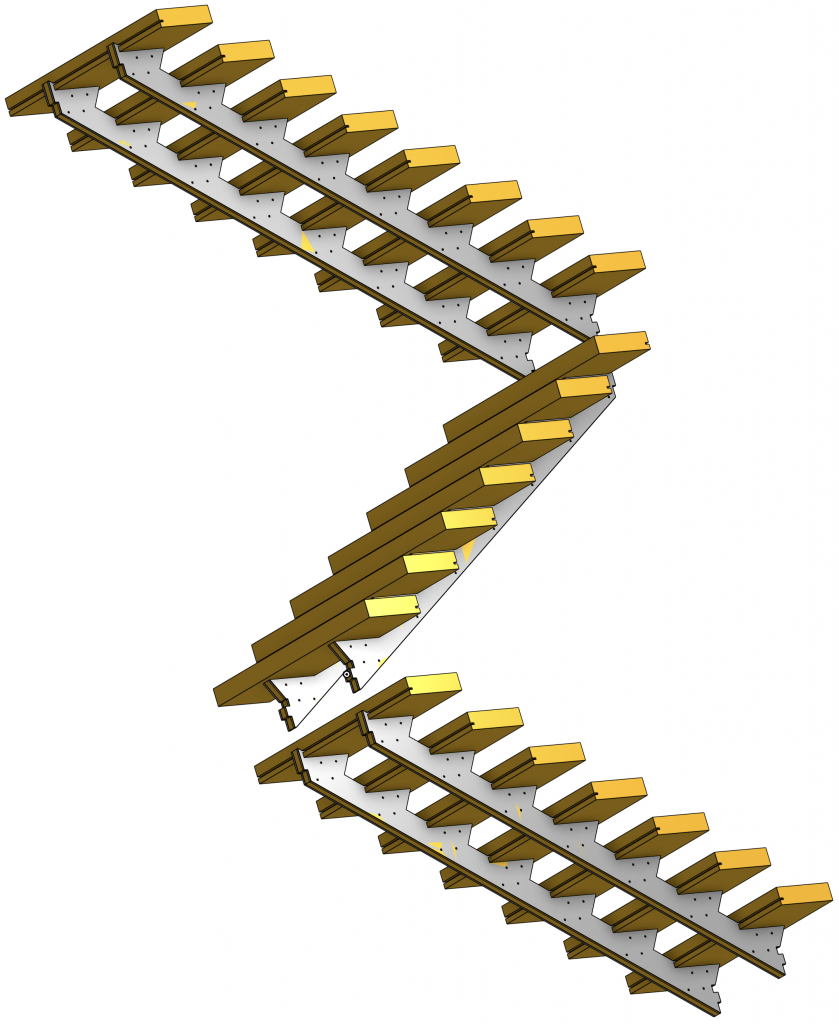

I also completed the design of the stair stringers we will be using for our floating staircase. The original plan was to use a custom solution from a company called ViewRail. At $10K per flight (4 flights needed) that was a rather expensive solution. Next, I had the project quoted by a local welder with great reviews for this type of work. His price worked out to $6K per flight. Finally, I decide to use my own design and a local laser cutter service for a solution that will cost $3K per flight. Each flight will use four stringers made from 3/8″ thick steel plate. Two plates will be sandwiched around an LVL 2×4 for each of the two stringers. Laser cutting will provide virtually identical parts with perfect angles and dimensions eliminating the need for any means to level the treads and saving a ton of time during installation. I included features in the stringer to make them easy to hang and also to capture the treads with minimal hardware. The grooves shown on the back of the treads will engage with tongues cut into the stringers. The final execution will use properly placed holes to capture the tongues rather than the long slot for a cleaner look.

Parking Practice

In a few weeks, it will be time to excavate our current driveway to bring in a new water line from the street. Concord requires this of any new construction on an existing site where the water main is older than 50 years. With the number of trees on our property, the driveway is the only path that is feasible. As long as we are forced to excavate, we will also have the power, fiber optic, cable, and phone lines buried. Since we have added an attached garage that will replace the existing garage/carport, it will be necessary to reroute the end of the driveway as well. In doing so, we are required to make no net change to the total surface area of the driveway to comply with requirements established by the Natural Resources Commission. I spent several hours today laying out the new driveway (red paint line) which will include a turn around area that also serves as a parking for two cars. I established the contours by driving my car through every scenario to ensure that an easy turnaround would be possible from any parking position. Later I mapped the curves to my computer model of the property so I could calculate the surface area of the new paved surface for comparison to the old. Fortunately, we will be under the limit.